Ignition components for hydrogen systems

High reliability and quality

Wide variety of design

Fuel cell reformer busbar

Supporting hydrogen industry

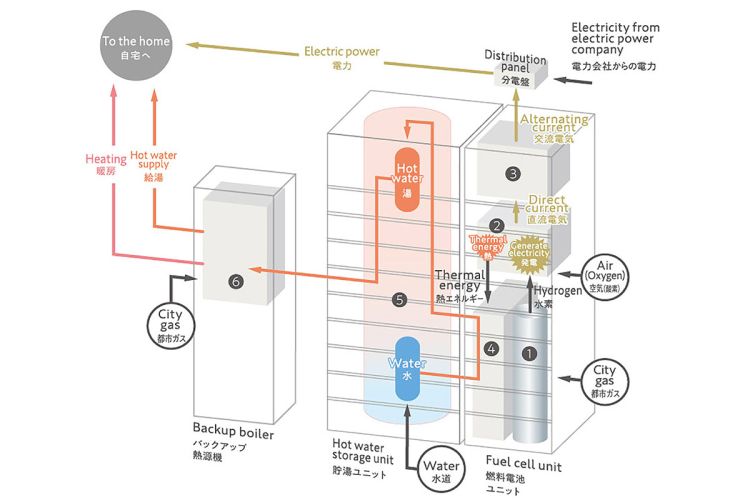

With support of Japanese industrial company, FKK Corporation committed to nature by developing renewable energy applications more respectful of our environment. Today greener solutions exist to reduce our impact on environment. Fuel cell Micro CHP SOFC, PEFC systems cost performance are very attractive and allow substantial energy saving as well as CO2 reduction.

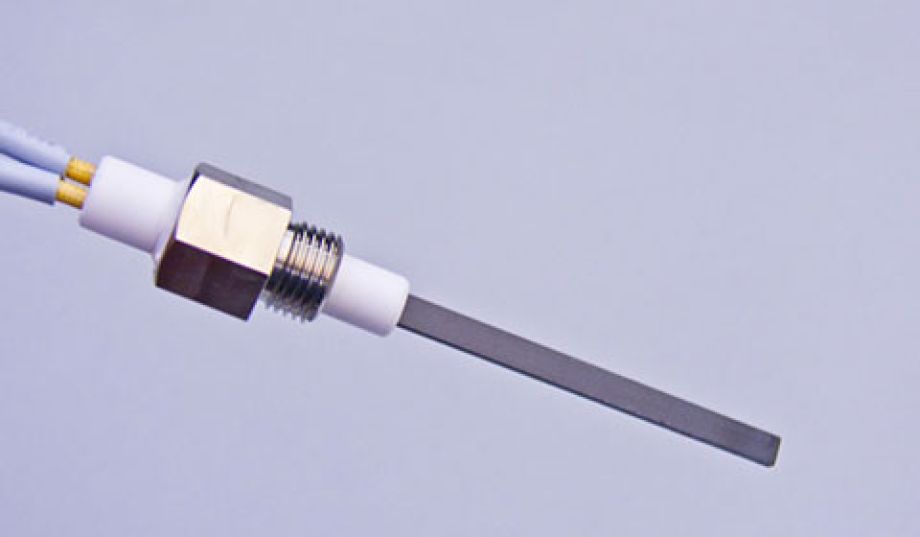

FKK produces SOFC/PEFC heat and power Fuel cell systems appliances enhanced ignition electrodes burner, high temperature SiN igniter for fuel cell cell system inerting burner, fuel reformer start burner, off-gas burner, cathode air preheater, anode gas oxidizers and gas preheater.

FKK provide all the Japanese Fuel cell system makers as well well as abroad MCHP SOFC systems maker with advanced ceramics igniters allowing long rated life (up to 90000 hours), high reliability, high temperature (up to 1300°C) and good sealing properties (lead wire temperature junction below 150-300°C). With high temperature performance you save energy on start-up burner gas pre heating operation, off-gas burner exhaust gas combustion as well as air preheating.

Applications

- Micro CHP : SOFC / PEFC (high temperature)

- Back-up power

- Back-up water heater unit

- Gas pre-heating

- Start-up burner

- Off-gas burner

- Cathode air preheater

- SOFC high temperature reformer

- Desulfurization unit

- Hydrogen direct combustion burner

- Hydrogen direct combustion boiler

- H2 ignition and flame detection in low content mix

- Hydrogen Industrial burner

Specification

-

High reliability and qualityover 90000 hours (nearly 10 years) of rated life, Japanese quality

-

Very high temperature1350°C in 30s, 1000°C in less than 6s

-

RobustnessHigh pressure resistant and very low temperature at lead wire junction (below 100-300°C)

-

Save energyOnly 45-75 Watts at steady state

-

Competitive costby providing major fuel cell makers, we achieved high cost/quality performance

About fuel cell

Fuel cells are "power generation devices" which can continuously take out electricity generated by an electrochemical reaction between hydrogen and oxygen, unlike "batteries" which take out stored electricity, such as dry batteries and other primary batteries, and rechargeable secondary batteries.

A fuel cell utilizes electric energy resulting from an electrochemical reaction between oxygen and hydrogen supplied as fuel. Thus, because the fuel cell directly converts energy resulting from a chemical reaction into electric energy, it has high energy efficiency. Big expectations are placed on it as a clean, next-generation "power generating device" which only leaves water following a reaction between hydrogen and oxygen, and does not emit any waste.

The part of a fuel cell that generates electricity is called a "stack" which consists of an aggregate of MEAs. Each MEA is sandwiched between separators.

Each separator has a channel through which hydrogen (hydrogen-rich gas) as fuel is supplied to the MEA fuel electrode and oxygen to its air electrode. Electricity is generated by electrochemical reactions in these MEAs.

The energy efficiency of a fuel cell is generally between 40-60%, or up to 85% efficient if waste heat is captured for use. Japense CHP energy efficiency is 70% and in addition of providing hot water it can cover 70% of normal house electricity consumption.